The Diagnostics of Induction Motor Broken Rotor Bars on the Basis of the Electromotive Force Analysis – Nova Science Publishers

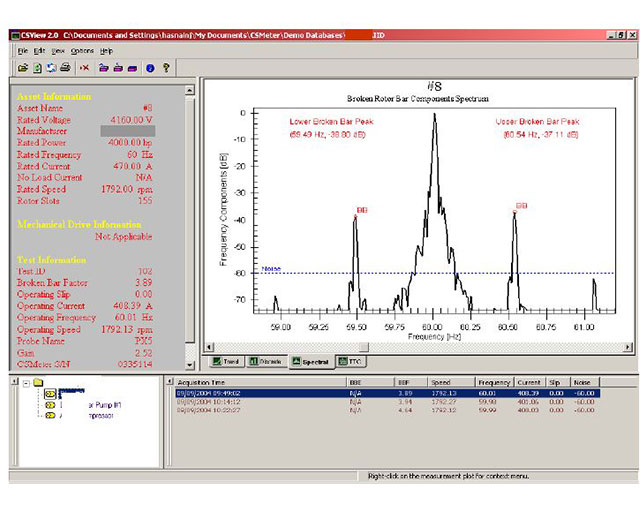

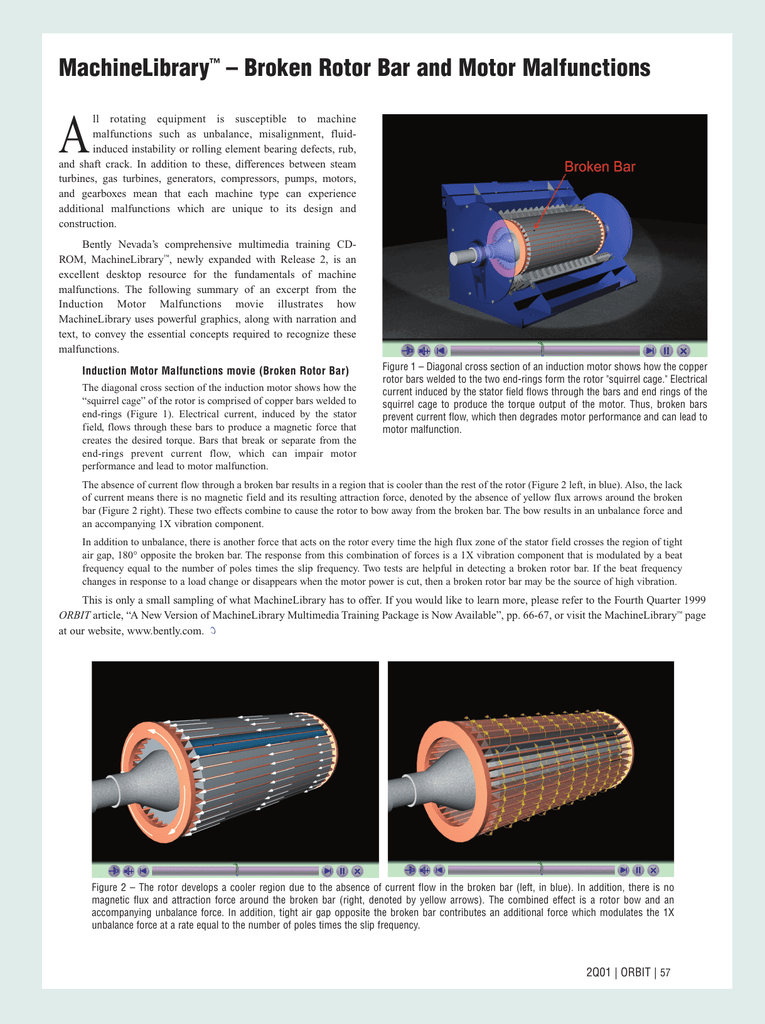

IBPSO-Based MUSIC Algorithm for Broken Rotor Bars Fault Detection of Induction Motors | Chinese Journal of Mechanical Engineering | Full Text

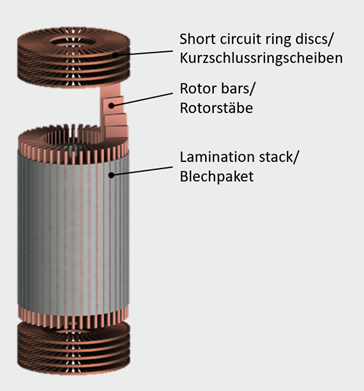

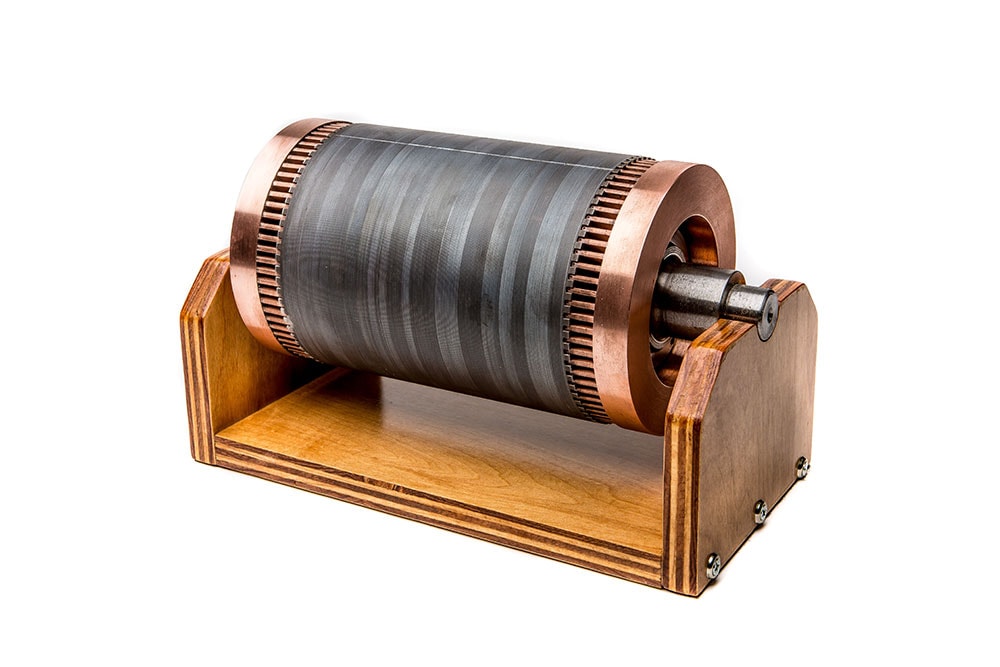

A comparison of rotor bar material of squirrel-cage induction machines for efficiency enhancement purposes | Semantic Scholar